Plac Gwarków 1, 40-166 Katowice, Poland

Head

e-mail: mwieckowski@gig.eu

telefon: 32 259 25 64

Head

mgr inż. Tomasz Goliwąs

e-mail: tgoliwas@gig.eu

telefon: 32 32 46 501

Head

e-mail: adudzinska@gig.eu

telefon: 32 259 21 27

Head

e-mail: mkarbownik@gig.eu

telefon: 32 3246 503

The Department of Mining Aerology performs scientific and research works for mining and non-mining entities in the field of ventilation, air-conditioning and fire hazard prevention. The Laboratory of Coal Spontaneous Combustion specializes in forecasting, assessing and fighting fire hazard in hard coal mines based on constant monitoring of the mine atmosphere in the areas of exploited longwalls. Comprehensive chromatographic analysis of mine air samples and the possibility of trace determination of such gases as acetylene, ethylene, propylene, hydrogen, carbon monoxide and isotopes of hydrogen and oxygen allows an objective evaluation of the development of the self-heating process in coal mines. The Laboratory has fully automated and modern measuring equipment necessary for fast and very precise determination of the selected components of mine air as well as for performing tests on coals. The equipment consists of 10 gas chromatographic stations, 2 gas chromatographic/mass spectrometric stations, sorption station and several calorimetric stations, each of them equipped with specialized software for recording and processing the results of performed analysis.

- Thermal testing of air-conditioning equipment

- Mine air-conditioning methods

- Mapping of rock primary temperature isolines for designed extraction levels and deposits

- Evaluation of geothermal conditions based on maps of rock primary temperature isolines for active and designed extraction levels and coal seams

- Prediction of climate hazard in the workings ventilated by both the main and auxiliary ventilation systems

- Development of model climatic solutions for underground workings with auxiliary ventilation

- Development of effective climate hazard prevention methods for mining panels

- Tests and implementation of solutions to improve the operation efficiency of mining cooling equipment

- Design of ventilation and air-conditioning systems for deep extraction levels and entire mines

- Expertise on reducing air-conditioning costs

- Rules of employing miners in hot microclimate

Scope of mine ventilation

- Ventilation system design for mines, industrial sites and structures

- Analysing ventilation costs, and reviewing methods for their reduction

- Preparing mine ventilation system plans and air flow diagrams, and their analyses

- Expert opinions concerning methane, dust, fire and radiation hazard prevention by means of ventilation measures

- Preparing main fan characteristics according to standard PN-70G-04161, and analysing the stability and efficiency of their operation

- Inspecting gas migrations in mine workings using the SF6 tracer gas

- Inspecting site airtightness using the SF6 tracer gas

- Variant-based analysis for simplifying the ventilation system models of decommissioned mines under the conditions of co-occurring gas hazards

- Developing working isolation technologies in decommissioned gassy mines

- Taking pictures of potential mine ventilation systems

- Computer-based characteristics of mine ventilation systems using the Ventgraph program

- Ventilation tubing system design

- Designing auxiliary ventilation systems for gallery workings driven in gassy deposits

- Tests and assessments of gas hazards for successive stages of decommissioning for the workings, areas, levels and shafts of decommissioned mines

- Numerical calculations (3D) of forecast air propagation in underground workings, and calculations of dust and methane concentrations in the ventilation air

- Numerical calculations with analyses of the ventilation systems of planned extraction areas under the conditions of methane and spontaneous fire hazard occurrence

- Numerical calculations and design of extraction work for extraction areas beneath the development level

- Developing working isolation technologies in decommissioned mines

- Designing tunnel ventilation during tunnelling and extraction

- Energy performance tests of blower fans, pumps, compressors

- Numerical calculations and design of extraction work for extraction areas beneath the development level

- Numerical calculations with analyses of the ventilation systems of designed extraction areas under the conditions of methane and spontaneous fire hazard occurrence

- Ventilation tube drag testing

Scope of mine air conditioning

- Preparing virgin rock temperature isolines for planned extraction levels, coal seams and copper ore beds

- Assessing geothermal conditions based on virgin rock temperature isolines for active and planned extraction levels, coal seams and copper ore beds

- Forecasting climatic hazards in workings with auxiliary ventilation (tubing) systems

- Forecasting climatic hazards in workings with main air currents

- Testing and assessing climatic hazards for workstations

- Forecasting climatic hazard states for designed workings ventilated via ventilation tubing

- Forecasting climatic hazard states for designed workings ventilated via recirculation of air

- Designing ventilation and air conditioning for deep extraction levels and the entire mine

- Evaluating the preventive measures taken against climatic hazards

- Preparing conceptual designs of combined air conditioning systems

- Formulating expert opinions on mining plant operations for group XX (climatic hazards) regarding preventive measures ensuring the maintenance of appropriate effective temperature in workings driven in a rock mass exhibiting a virgin temperature higher than 40oC

- Thermal testing of electrical equipment

- Preparing effective preventive measures against climatic hazards for extraction areas

- Testing and implementing solutions for the improvement of mine cooling system efficiency

- Measuring and analysing the efficiency of mine cooling systems based on in situ measurements

- Expert opinions concerning lower air conditioning costs

- Defining the principles of employing miners in hot microclimates

Scope of gas hazard prevention

- Forecasting methane emissions to extraction, preparatory and development workings

- Opinions regarding the classification of coal seams or their parts and methane fields into the appropriate categories of methane hazards and gas and rock outburst hazards

- Classifying workings (rooms) with regard to the appropriate levels of methane explosion risks

- Complex assessment of methane hazards and spontaneous fire hazards in planned extraction areas

- Simulations and analyses of the methane content distribution in coal seams

- Assessment of the generation of methane hazards for mined longwalls, factoring in the ventilation and methane conditions and the scope of applied preventive measures

- Balancing the free methane accumulated in decommissioned mine workings in conventionally adopted time intervals, in relation to hydrogeology, tectonics and conditions related to adjacent mines

- Forecasting the likelihood of gas hazard occurrence on the surface within the area of a decommissioned gassy mine

- Testing the kinetics and flow intensity of mine gases into the near-surface zone within the area of a decommissioned mine

- Developing methods for the active prevention of gas hazards in near-surface zones within the post-mining areas of decommissioned mines

- Developing deposit stimulation technologies for increased deposit permeability and for the pre-extraction methane drainage of coal seams (hydroslotting), and CBM support technologies

- Assessment of the generation of methane hazards for mined longwalls, factoring in the ventilation and methane conditions and the scope of applied preventive measures, including methane drainage

- Developing technologies for methane recovery from coal deposits and use

- Expert opinions regarding the methane drainage methods applied in extraction areas

- Designing methane drainage systems in mines and the trajectories of directional boreholes

- Analysing the methane and rock outburst hazards in coal seams or their parts with regard to the classification and delimitation of classification into the appropriate categories of outburst hazards, and with regard to preventing said hazards

- Balancing the free methane accumulated in decommissioned mine workings in conventionally adopted time intervals, in relation to hydrogeology, tectonics and conditions related to adjacent mines

- Forecasting the likelihood of gas hazard occurrence on the surface within the area of a decommissioned gassy mine

- Testing the kinetics and flow intensity of mine gases into the near-surface zone within the area of a decommissioned mine

- Developing methods for the active prevention of gas hazards in near-surface zones within the post-mining areas of decommissioned mines

- Forecasting methane capture from extraction boreholes (CBM) and surface boreholes to virgin coal seams, i.e. outside extraction range, (CBM) based on the results of numerical modelling using the Petrel, Eclipse and AnSys CFX software

Scope of gas and rock outburst hazard prevention

- Forecasting the state of outburst hazard for newly-developed and poorly explored parts of a deposit

- Conducting in situ measurements of the basic indicators of outburst hazard states used for coal mines, i.e. methane desorption intensity, methane content, volume of borings and coal cohesion, in order to provide an assessment of the current state of the outburst hazard or to prepare a current forecast

- Analysing the methane and rock outburst hazards in coal seams or their parts with regard to the classification and delimitation of classification into the appropriate categories of outburst hazards, and with regard to preventing said hazards

- Conducting complex tests of coal seams (rocks) in order to determine their predispositions for outbursts, encompassing extended measurements involving sorptive properties, i.e. sorption kinetics and effective diffusivity

- Formulating opinions regarding the technical design of mining activities conducted under the conditions of outburst hazards, planning deposit (coal seam) development, and designing ventilation systems and protections under the conditions of the aforementioned hazards

- Delimiting the classification of a coal seam into the appropriate outburst hazard category, and formulating opinions concerning the possibility of excluding a part of the coal seam from the boundaries of its current classification into an appropriate outburst hazard category

- Assessing the effectiveness of preventive measures taken against outbursts in mines and preparing the (principles of) preventive measures for specific mining activities performed in zones exhibiting a particularly high risk of hazard occurrence

- Analysing sorption isotherms in order to determine the coal seam pressures and predispositions for outburst (gasogeodynamic phenomenon occurrence)

- Delimiting extraction degassing zones in an analysed coal seam and simulating the distribution of remaining methane content with regard to opinions and forecasts concerning outburst hazards

- Simulating the distribution of methane content and coal seam gas pressures in a deposit

- Analysing the changes in the basic indicators of the state of outburst hazard, i.e. methane desorption intensity, coal cohesion, and assessing the influence of geological disturbances (faults) on the geotechnical properties of coal seams

- Investigation into susceptibility of coals to spontaneous combustion

- according to PN-93/G-04558 standard

- using the calorimetric method

- Determination of critical conditions for spontaneous combustion of coal in the seam

- Development of a model of gas emission from the heated fragment of coal deposit

- Monitoring of fire hazard level in coal mines based on the precise chromatographic analysis (trace content of carbon monoxide, ethylene, propylene, acetylene and hydrogen and oxygen isotopes) of gas samples together with a current risk assessment

- Prediction of fire hazard in mines together with a risk assessment

- Monitoring of the process of fire suppression and cooling of heated coal mass in sealed off workings based on the precise chromatographic analysis of gas samples

- Determination of conditions for safe opening and ventilation of the workings sealed off due to fire hazard

- Elaboration of the principles for effective fire prevention:

- determination of minimum longwall advance on grounds of fire hazard

- selection of an inert gas

- selection of means that limit air flow through the gobs

- elaboration of principles for prevention based on the use of inhibitors of spontaneous combustion process

- Selection of the equipment and measures necessary for extinguishing fires

- Extinguishing of underground fires by means of active and passive methods

- Investigation into spontaneous combustion of various materials

- Organization and completion of equipment for laboratories performing research relating to:

- early detection of endogenous fires based on the trace content of selected gases in air samples

- susceptibility of coals to spontaneous combustion

- Determining the rules for fire detection in tunnels

Since 1998 we have been accredited by the Polish Centre for Accreditation (Accreditation Certificate AB 005).

- Determination of methane content using direct method.

Coal degassing stand using the MOD-2

- Desorption tests using United States Bureau of Mines (USBM) method.

Tests include:

- Determination of lost gas, desorbing gas and residual gas,

- Determination of the composition of desorbing and residual gas by gas chromatography,

- Determination of final methane content.

Stand for desorption tests (USMB)

- Determination of physical and chemical parameters of solid fuels:

- ash content (A),

- expiring moisture (Wex),

- hygroscopic moisture (Wh),

- moisture in the analitical sample (Wa),

- total moisture (Wt)

- voltalite matter (Vdaf),

- density by helium pycnometry (dr). - Research on the desorption of methane from coal under variable hydrostatic pressure conditions.

- Determining coefficient of rocks’ conciseness (fz).

- Chromatographic analysis of mine air: O2, N2, H2, CO2, CO, CH4, C2H6, C2H4.

- Chromatographic analysis of the following gases: O2, N2, H2, CO2, CO, CH4, C2H6, C2H4, C2H2, C3H8, C3H6, n- C4H10.

- Detection of flammable and toxic gases hazardous concentrations: O2, CO2, CO, CH4, H2S, SO2, NO2, NO.

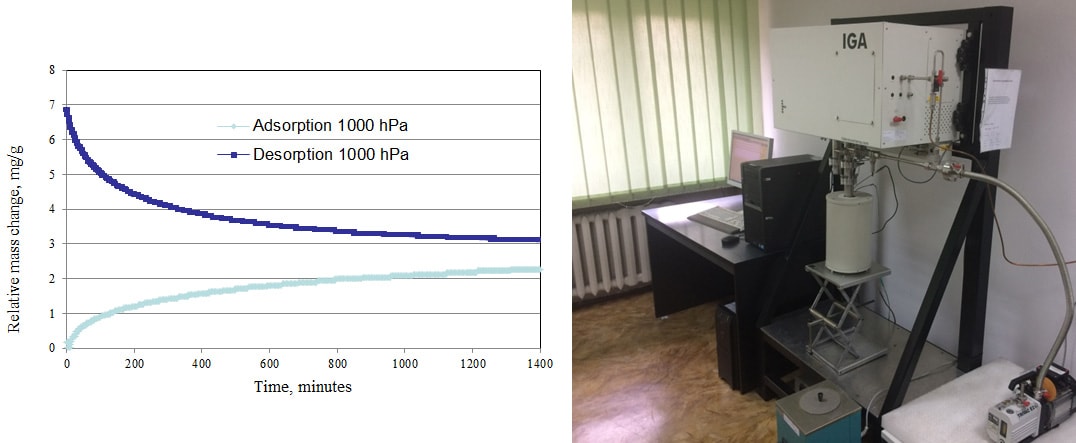

- Determination of sorption parameters:

- effective diffusion coefficient (De),

- sorption capacity (a),

- sorption capacity calculating into daf (adaf),

- sorption half-time (t0,5),

- determination of sorption isotherms based on Langmuir isotherm model.

Methane sorption and desorption changes tests using gravimetric

etting IGA-001 to determine sorption parameters of coal